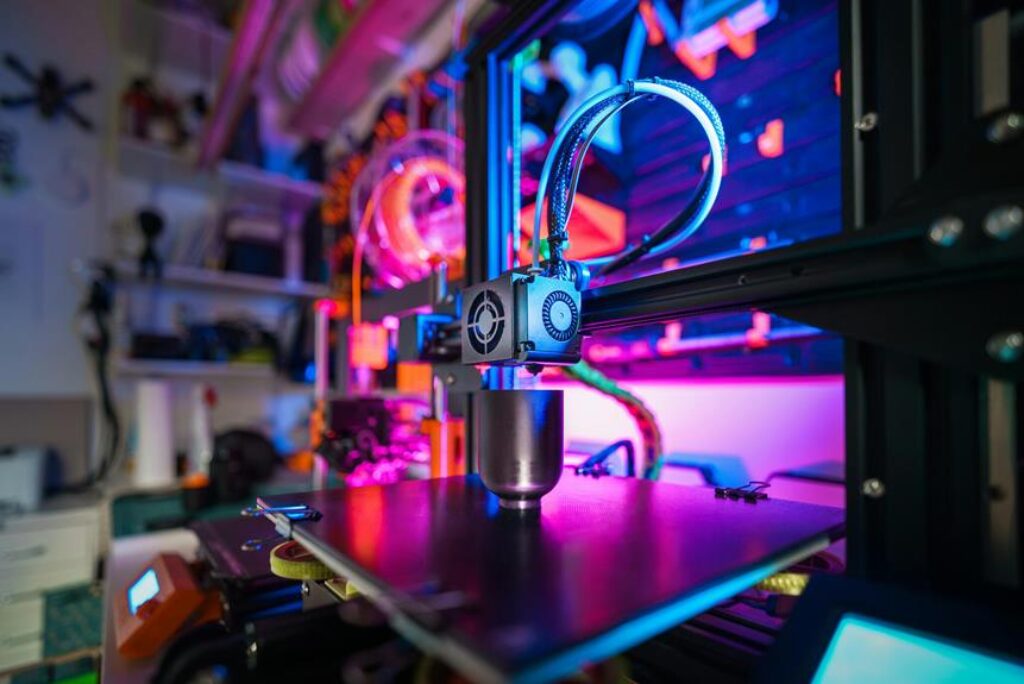

3D printing techniques have been making significant strides in transforming car manufacturing processes. The precision and speed at which 3D printers can create intricate car parts have opened up new possibilities for the industry. Imagine a world where vehicles are not only manufactured faster but are also customized to suit individual needs seamlessly. The impact of 3D printing on car manufacturing goes beyond just efficiency; it's reshaping the way cars are designed, built, and ultimately, driven. Explore how this innovative technology is revolutionizing the automotive landscape.

Advantages of 3D Printing in Car Manufacturing

When implementing 3D printing in car manufacturing, cost savings and increased efficiency are two key advantages that companies can benefit from. By utilizing 3D printing technology, you can dramatically reduce production costs compared to traditional manufacturing methods. The ability to create complex car parts in a single print job minimizes the need for multiple manufacturing steps, saving both time and money.

Moreover, 3D printing allows for on-demand production, enabling companies to manufacture specific car components as needed. This flexibility eliminates the need for maintaining large inventories of spare parts, reducing storage costs and minimizing waste. Additionally, the customization possibilities offered by 3D printing empower car manufacturers to tailor products to meet the specific requirements of customers quickly and efficiently.

Applications of 3D Printing in Automotive Prototyping

Exploring the diverse applications of 3D printing in automotive prototyping can revolutionize the development process and enhance design flexibility. One key application is the rapid production of prototypes for concept validation. 3D printing allows for the quick and cost-effective creation of physical models that can be used for testing various design aspects, such as aerodynamics, ergonomics, and overall functionality.

Moreover, 3D printing enables the customization of prototypes to meet specific requirements. Car manufacturers can easily iterate on designs and make adjustments based on feedback, leading to more refined final products. This level of customization and adaptability significantly speeds up the prototyping phase of development.

Additionally, 3D printing facilitates the production of complex geometries that traditional manufacturing methods struggle to achieve. This capability opens up new design possibilities and allows for the creation of innovative automotive components. By utilizing 3D printing in automotive prototyping, manufacturers can explore unconventional designs that may improve performance, efficiency, and sustainability in the automotive industry.

Impact of 3D Printing on Production Efficiency

3D printing's impact on production efficiency is evident in the streamlined manufacturing processes and reduced lead times experienced by car manufacturers. By utilizing 3D printing technology, car manufacturing companies can now produce complex car parts faster and more efficiently than traditional manufacturing methods. The ability to create prototypes and functional parts directly from digital designs eliminates the need for expensive tooling and molds, saving both time and money in the production process.

Moreover, 3D printing allows for on-demand manufacturing, enabling car manufacturers to produce parts as needed, reducing inventory costs and storage space requirements. This just-in-time production approach minimizes waste and ensures that only necessary components are manufactured, further enhancing production efficiency.

Additionally, 3D printing facilitates rapid iterations and customization, empowering manufacturers to quickly test and modify designs to optimize performance and functionality. This agility in product development leads to faster time-to-market for new car models, giving companies a competitive edge in the automotive industry. Overall, the impact of 3D printing on production efficiency is transformative, revolutionizing the way cars are manufactured.

Future Trends in 3D Printing for Vehicles

Looking ahead, the automotive industry is poised to witness significant advancements in 3D printing technology for vehicles. One key trend on the horizon is the increased use of metal 3D printing in car manufacturing. This method allows for the creation of complex metal parts that are both lightweight and durable, enhancing overall vehicle performance.

Additionally, the integration of 3D printing with artificial intelligence and machine learning is set to revolutionize the design and production processes. By leveraging AI algorithms, manufacturers can optimize designs for improved aerodynamics, fuel efficiency, and safety.

Another exciting development is the shift towards large-scale 3D printing for vehicle components. This advancement will enable the production of entire car bodies in a single print, reducing assembly time and costs.

Furthermore, the adoption of sustainable materials, such as recycled plastics and bio-based polymers, is expected to play a significant role in shaping the future of 3D printing for vehicles, promoting eco-friendly practices in the automotive sector.